IELTS THƯ ĐẶNG- TRUNG TÂM LUYỆN THI IELTS UY TÍN, CHẤT LƯỢNG TẠI HÀ NỘI

Tham khảo các bài liên quan:

>>> Kinh nghiệm luyện thi IELTS

>>> Hướng dẫn làm bài thi IELTS

Dạng bài Process thường được chia làm 2 mảng chính: Natural Cycle (Quá trình Tự nhiên) hoặc Man-made Process (Quá trình Nhân tạo).

Đối với Natural Cycle, thí sinh sẽ được yêu cầu mô tả chu trình sinh trưởng của một loài sinh vật nào đó như ếch, bướm, hoặc quá trình hình thành mưa. Trong khi đó, với Man-made Process, đề bài có thể đề cập đến quá trình tạo ra một sản phẩm nào đó ví dụ như tạo ra dầu oliu, quy trình tái chế đồ nhựa…

Tuy nhiên, phương pháp và nguyên tắc làm bài mà bài viết này hướng dẫn sẽ được áp dụng tương tự đối với cả hai dạng.

Dưới đây là tổng hợp 20 bài mà IELTS Thư Đặng tổng hợp cả 2 dạng trên mà đã ra trong thời gian qua.

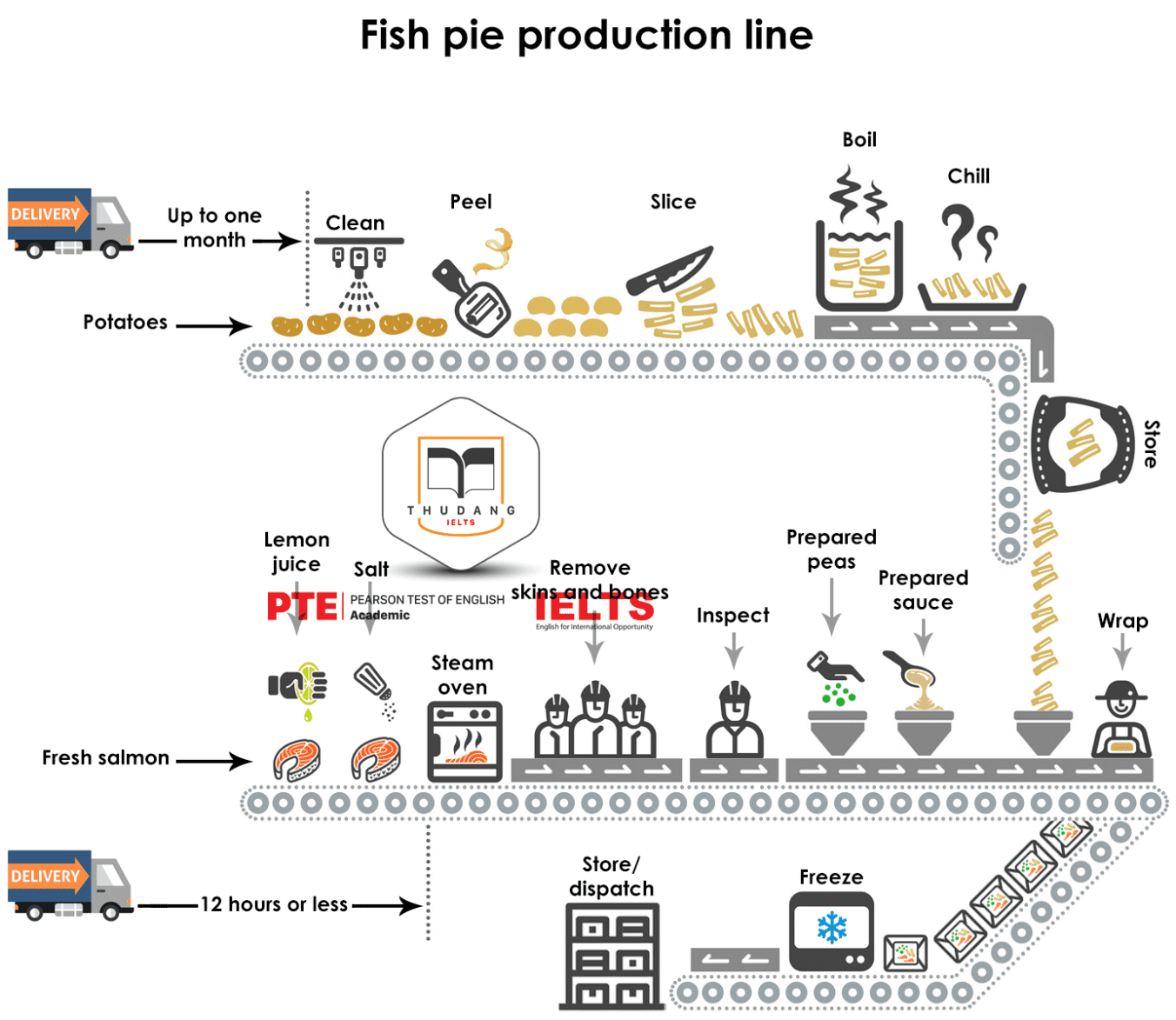

1. The diagrams below give information about the manufacture of frozen fish pies.

Summarise the information by selecting and reporting the main features, and make comparisons where relevant.

Sample answer

This diagram shows that there are a number of processes involved in the commercial production of frozen fish pies. The main ingredients consist of fresh salmon, peas and sauce, with sliced potatoes, and they are prepared separately. The potatoes, which may have been delivered up to a month in advance, are cleaned, peeled and cut into slices. The slices are boiled and then chilled before being stored until needed. The preparation of the fish is more labour intensive than the preparation of the potatoes. Within twelve hours of being delivered to the factory, the fresh fish is cooked by being steamed with lemon juice and salt. Then the skin and bones are removed by hand and disposed of, before a visual inspection takes place.

After this, the pies are assembled in microwaveable containers Peas and sauce, which have also been prepared, are added to the fish and then the pie is covered with a layer of cooked potato slices. The pies are then wrapped and frozen. At this point they are ready for dispatch, or they may be stored at the factory before being dispatched.

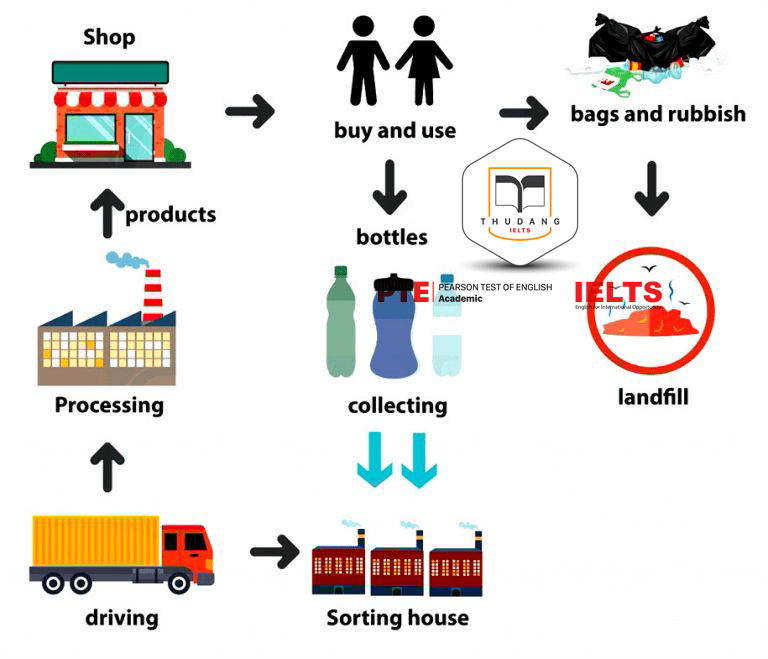

2. The diagram below shows the recycling process of plastics.

Summarise the information by selecting and reporting the main features, and make comparisons where relevant.

Sample answer

The diagram illustrates how plastic bottles are recycled.

There are seven main stages in the process of recycling plastic bottles, beginning with consumers using them and ending with making them into new products.

First of all, plastic bottles are bought and used by consumers. After that, they are used up and thrown into the recycling bin. The process continues with plastic bottles being taken to the recycling plant. Subsequently , they are put in the washer for cleaning all the impurities.

In the next step, plastic bottles are shredded into small pieces. After going through the shredder, tiny fragments of plastics are then converted into pellets by an extruder. The process concludes with pellets being made into new products.

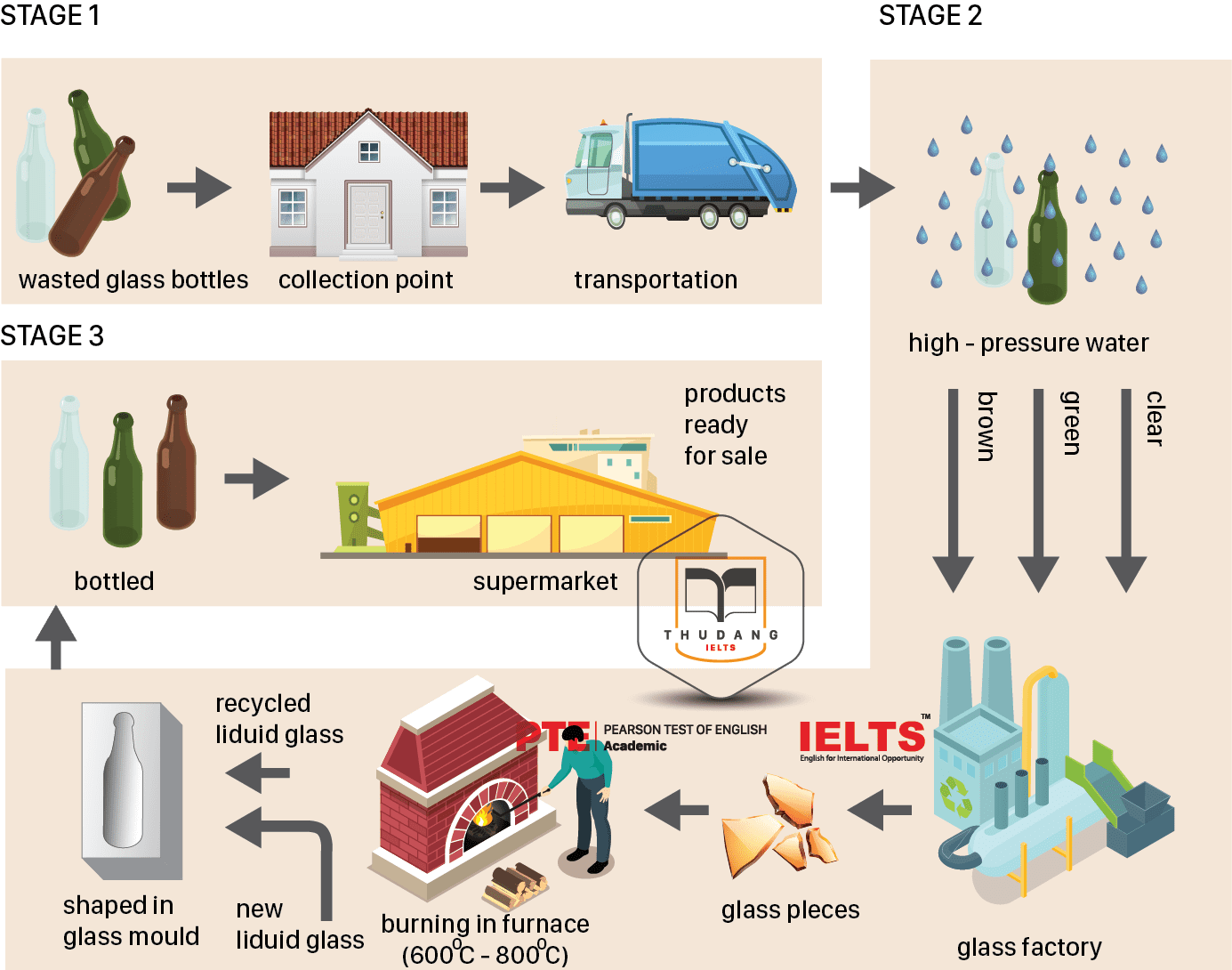

3. The diagram below shows the process of recycling glass bottles.

Sample answer

The diagram illustrates how wasted bottles made from glass are recycled and delivered back to the store.

Overall, there are 3 main stages in the whole glass bottle recycling process, beginning with collecting wasted jars and finishing with the delivery of the products for sale.

In the first stage, wasted glass jars are deposited at collection points where they are loaded on trucks to transport to a glass treatment plant. In the second stage, several steps are taken in order to transform the wasted glass to recycled products. Firstly, bottles are washed under high-pressure water to remove any impurities, following that they are classified into 3 categories based on the colour, namely clear, green and brown glass. They are then transferred to glass factories in which they are crushed into debris. In the next step, those pieces are melted in a glass-melting furnace at around 600 to 800 degree Celsius. After that, recycled liquid glass together with new liquid glass is moulded into new products.

In the last stage, the glass is used to bottle different products and then sent back to the supermarket ready for sale.

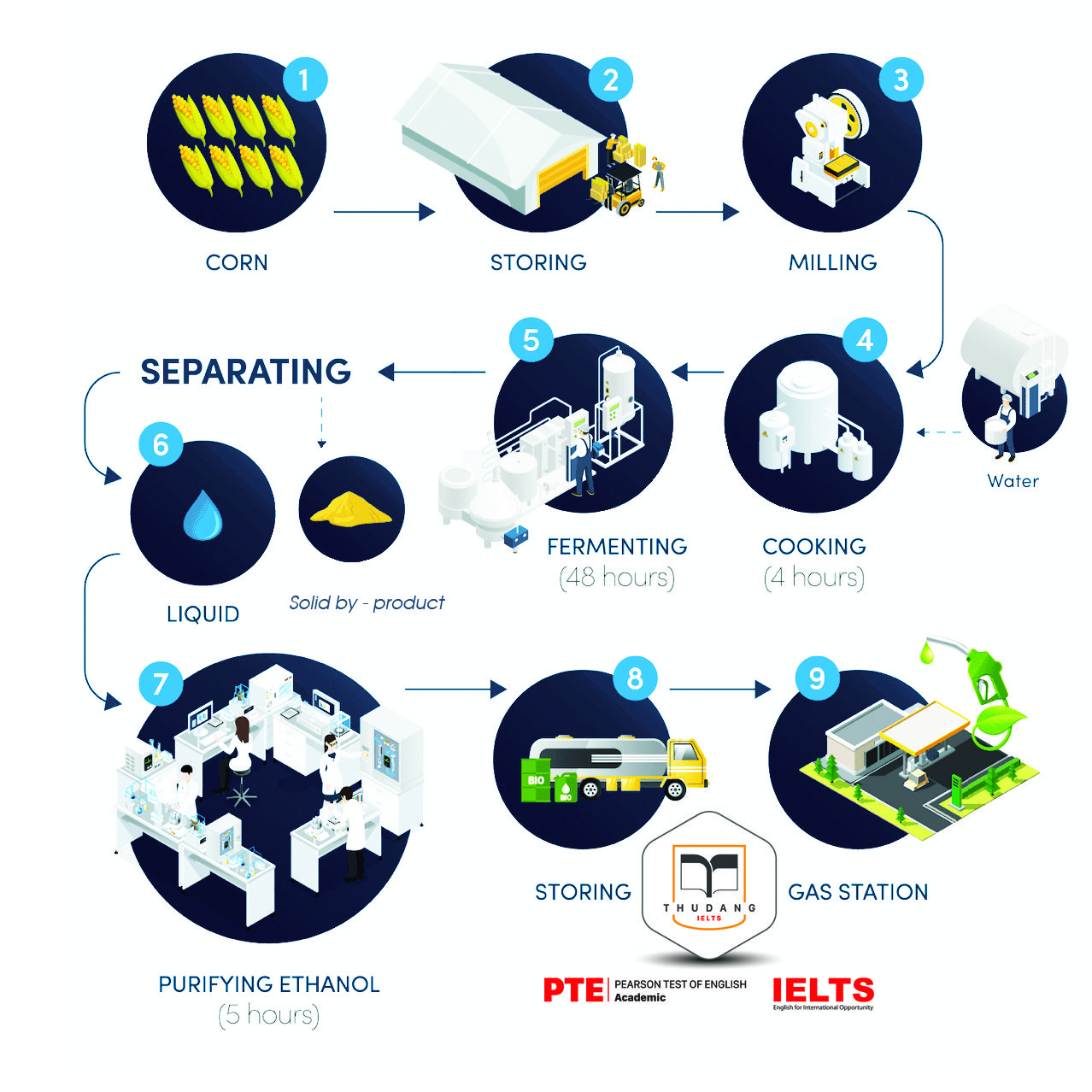

4. The diagram below shows how ethanol fuel is produced from corn

Sample Answer:

The diagram shows the various steps of the production of corn-based ethanol. Overall, there are a total of 8 steps to produce ethanol fuel from corn.

First, corn is harvested from fields. Then, it is stored to commence the production of ethanol. The first step of the production is milling the corn and grinding it into powder. In the next step, the milled corn goes through the cooking stage in which it is mixed with water. The following step is that the mixture of corn powder and water is fermented.

After the process of fermentation, solid product is separated from the liquid which is purified in the last chemical step of the corn ethanol production. It takes 5 hours for purification to make the final product which is ethanol. Once the ethanol fuel is ready, it is stored before being delivered to where it is consumed.

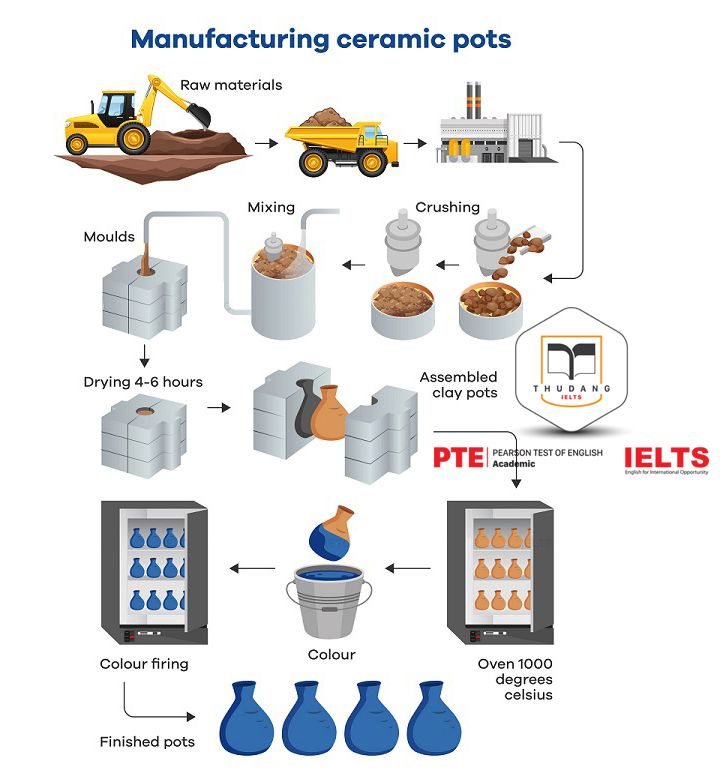

5. The diagram below shows one way of manufacturing ceramic pots.

Sample Answer:

The diagram shows one of the possible ways to produce ceramic pots. Overall, there are a total of 11 steps in the process of ceramic pots production.

First, raw materials to make ceramic pots are dug out of the ground by a digging machine before being transported by a truck to a factory where the next 8 steps pots are followed to manufacture ceramic spots.

At the factory, the raw materials are crushed into powder by a machine. In the next step, the powder is mixed with water, and then this mixture is poured into moulds that form the mixture in the shape of a pot. Then, these moulds are dried from 4 to 6 hours to create assembled clay pots. Next, the clay pots are placed into an oven and heated at a temperature of 1000 degrees Celsius. Once they are ready, they are coloured and heated in another oven for colour firing. The outcome of this step is the final products which are finished ceramic pots.

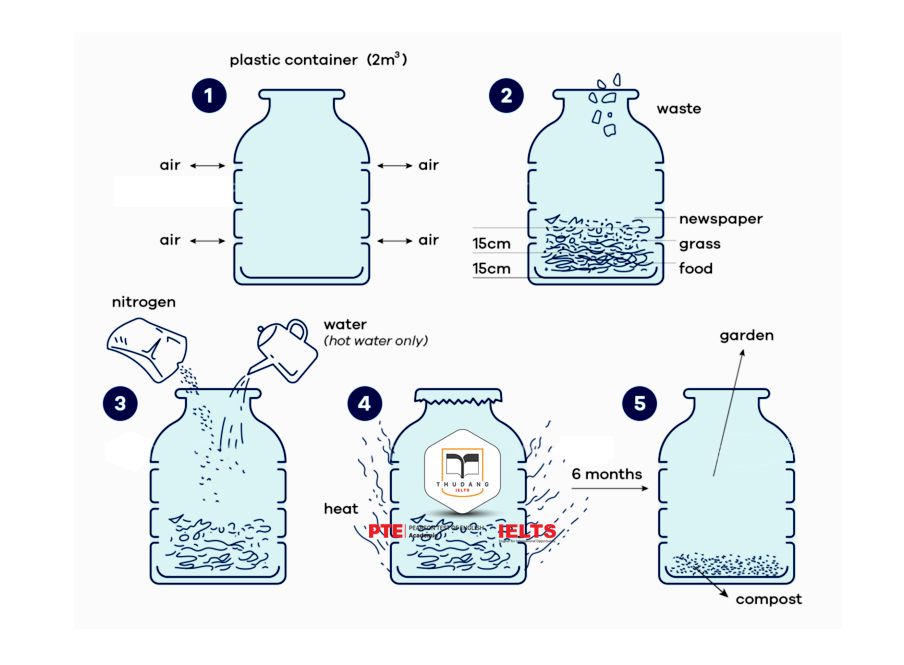

6. The diagram below shows how to recycle organic waste to produce fertiliser (compost). Summarize the information by selecting and reporting the main features and make comparisons where relevant.

Sample Answer:

The diagram shows the production of fertiliser, or compost, by recycling organic waste. Overall, there are a total of 5 stages to produce compost from waste.

First, to prepare for the recycling process of organic waste, a plastic container with 2 cubic meters in capacity is required. Also, air is needed for the production of compost, so it is allowed to penetrate inside throughout several air slots on walls on the body of the container.

In the next step, small pieces of organic waste are dropped into the container to form 3 layers of food, grass, and newspaper respectively, with 15 centimetres for each. The following stage is that nitrogen and water at high temperature are added with waste to create a mixture in the container which then is heated continuously over 6 months. During this heating stage, the gas released from the mixture heated escapes through the air slots. After 6 months, the product which is compost is finally formed and ready to go for gardening.

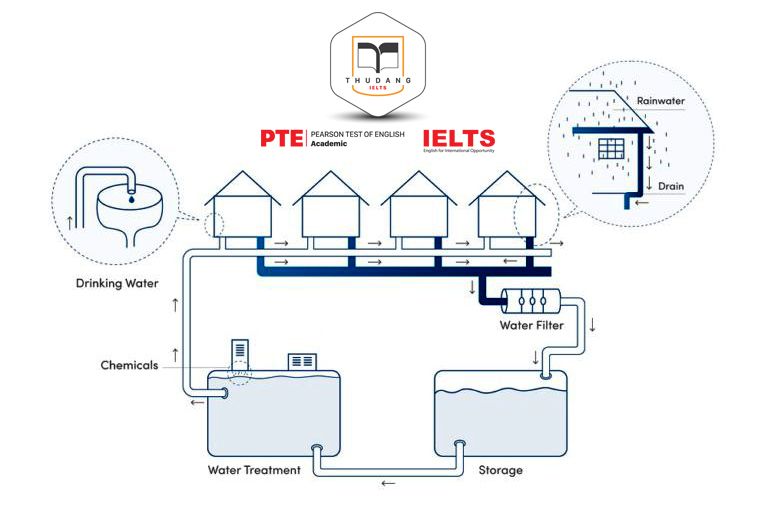

7. The diagram shows rainwater is collected for the use of drinking water in an Australian town. Summarize the information by selecting and reporting the main features and make comparisons where relevant.

Sample Answer:

The diagram illustrates how an Australian town collects rainwater to process in order to use as drinking water. Overall, rainwater collected from the rooftops has to be processed by chemical and filtered, before it can be used as drinking water.

Initially, the rain which falls on the rooftop is collected by the gutter and then runs down the pipe at the side of the house into the drain located under the ground. Each houses collect rainwater in such a way and passed along underground drains to the water filter.

The water filter removes any impurities and the water once filtered continues to flow into the storage tank for further processing. From this point, the water flows from the storage to the water treatment tank. Chemical added to the water for purification in order to make it fit for consumption. Once water is treated and made ready for drinking, it travels along the pipes that lead back to houses where people can use it for daily consumption.

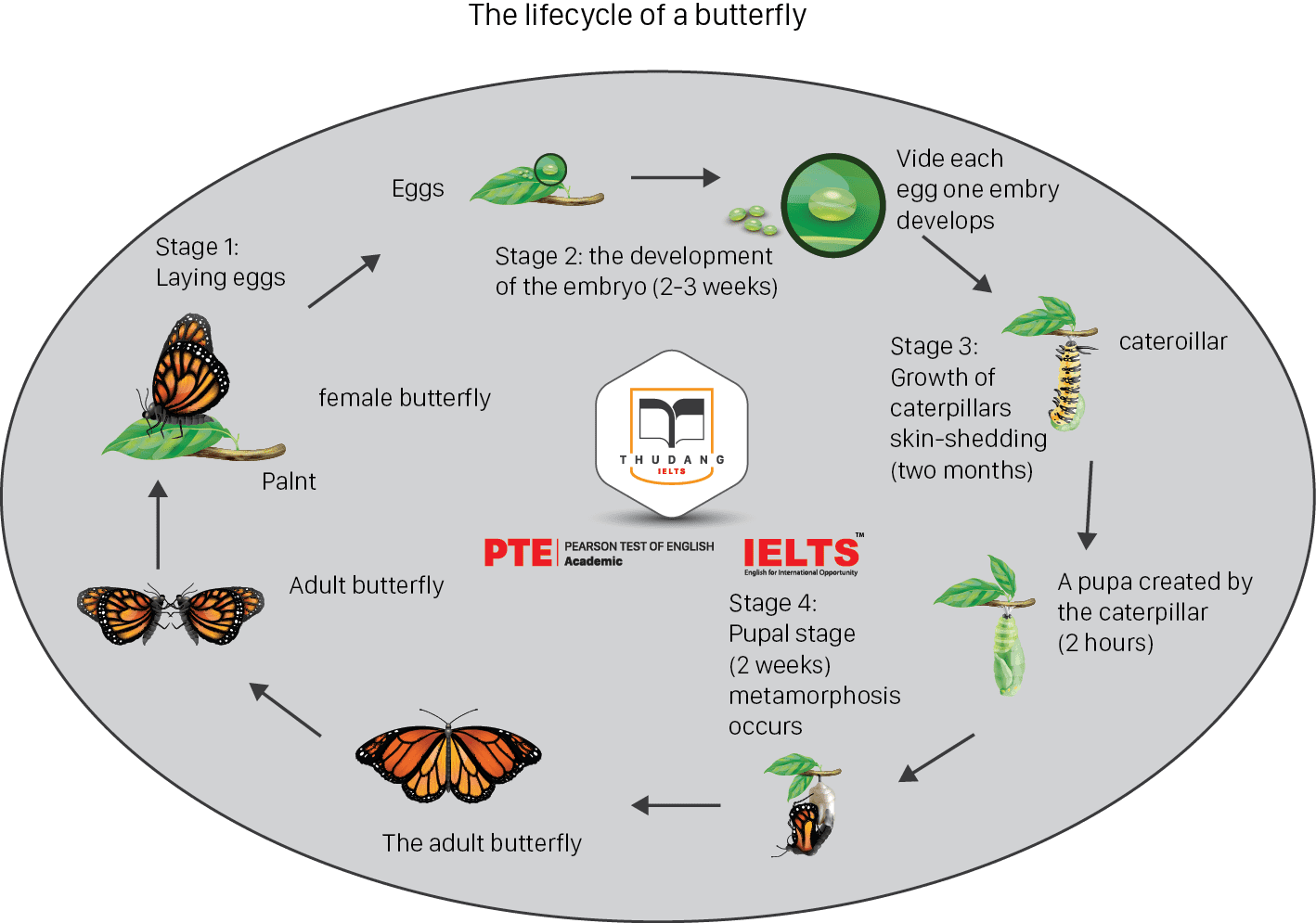

8. The diagram below shows the life cycle of the butterfly. Summarise the information by selecting and reporting the main features and make comparisons where relevant.

Sample Answer:

The life cycle of a butterfly starts from egg laying. The female butterfly normally lays eggs on a plant that it thinks is suitable for accommodating and feeding caterpillars. In each egg, an embryo develops gradually. In general, this period takes two to three weeks. The fully-grown embryo, called “the caterpillar”, will emerge from the egg.

The next stage is skin-shedding. Caterpillars will shed their skin several times throughout this stage. They feed on the food plants where they live. This stage lasts for two months at most, until caterpillars are ready for the pupal stage.

The pupal stage is possibly one of the greatest wonders in the natural world. At this stage, the caterpillar wraps itself in a pupa, a creature it creates within two hours. Inside the pupa, a process known as metamorphosis takes place. In two weeks, the pupa is transformed into an adult butterfly.

At the final stage, the adult butterfly will break the pupal case, expand its wings and take the flight for the first time. It marks the end of metamorphosis. Flying around for new food plants, adult butterflies are ready to mate for a new cycle.

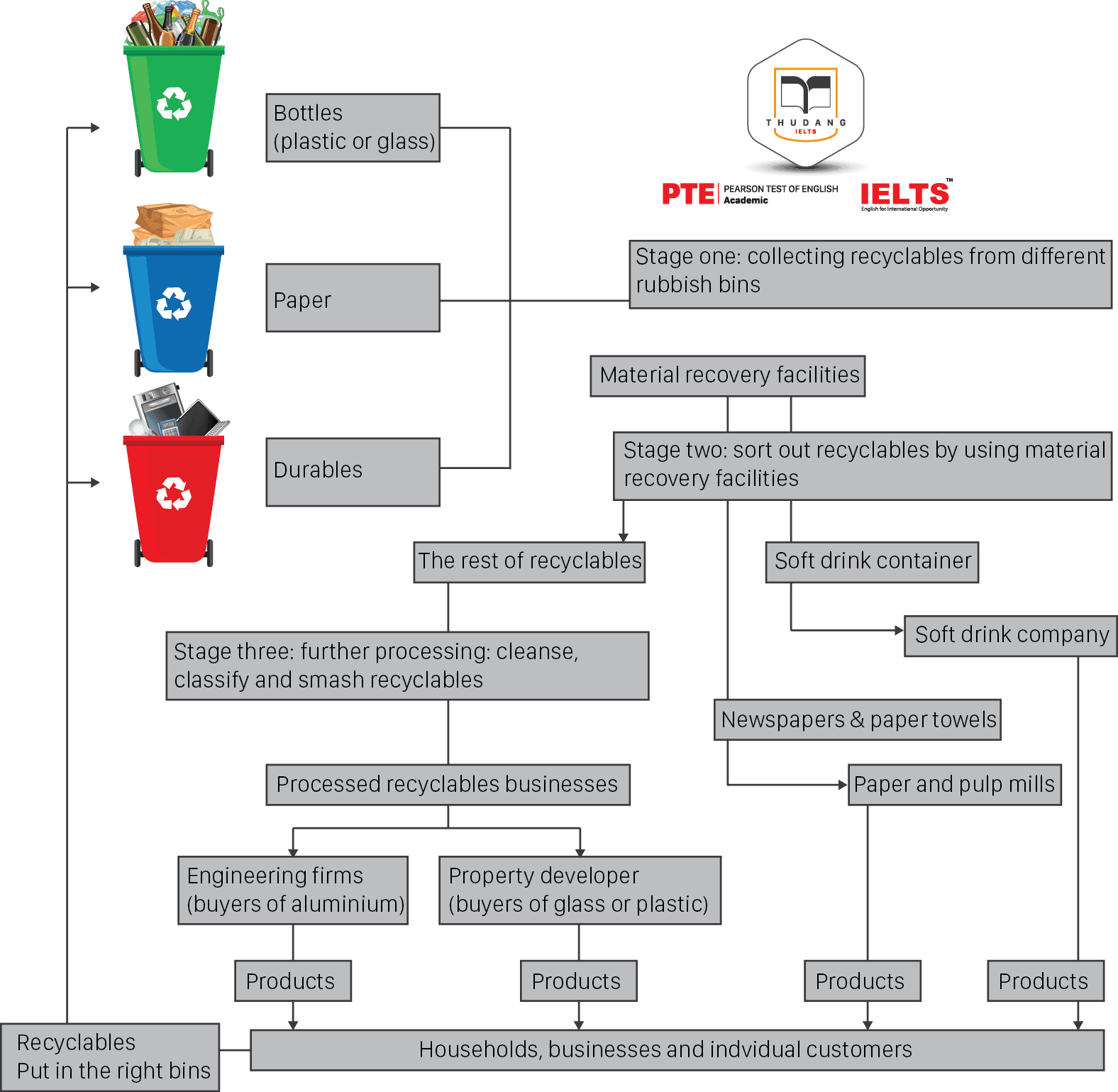

9. Write a description of how urban refuse is assorted for recycling. Use the information in the diagram and write a description of this process.

Sample Answer:

Collecting and processing recyclables plays an important role in the treatment of urban refuse. The first step is collecting recyclables from rubbish bins. Three main types of recyclables are bottles (plastic or glass), paper and durables. If rccyclablcs have already been put in the right rubbish bins, it will save plenty of time that is otherwise required for the second stage.

In the second stage, material recovery facilities will sort the recyclables more carefully. Part of recyclables will be sent to some customers for their own use. For example, soft drink companies have their own recycling facilities to take advantage of the soft drink containers collected. Newspapers and paper towels can be sent to paper and pulp mills.

The rest of recyclables will be cleaned, separated and smashed as the third part of the recycling loop, known as further-processing stage. The recycled materials produced are sold to different businesses. For example, engineering companies are regular buyers of aluminium, while properly developers will buy glass or plastic for various usages.

At the final stage, all the recycled materials will become part of the items used by households daily. Once those items are disposed, it is expected that households will put them in appropriate rubbish bins. It is how the recycling loop keeps operating.

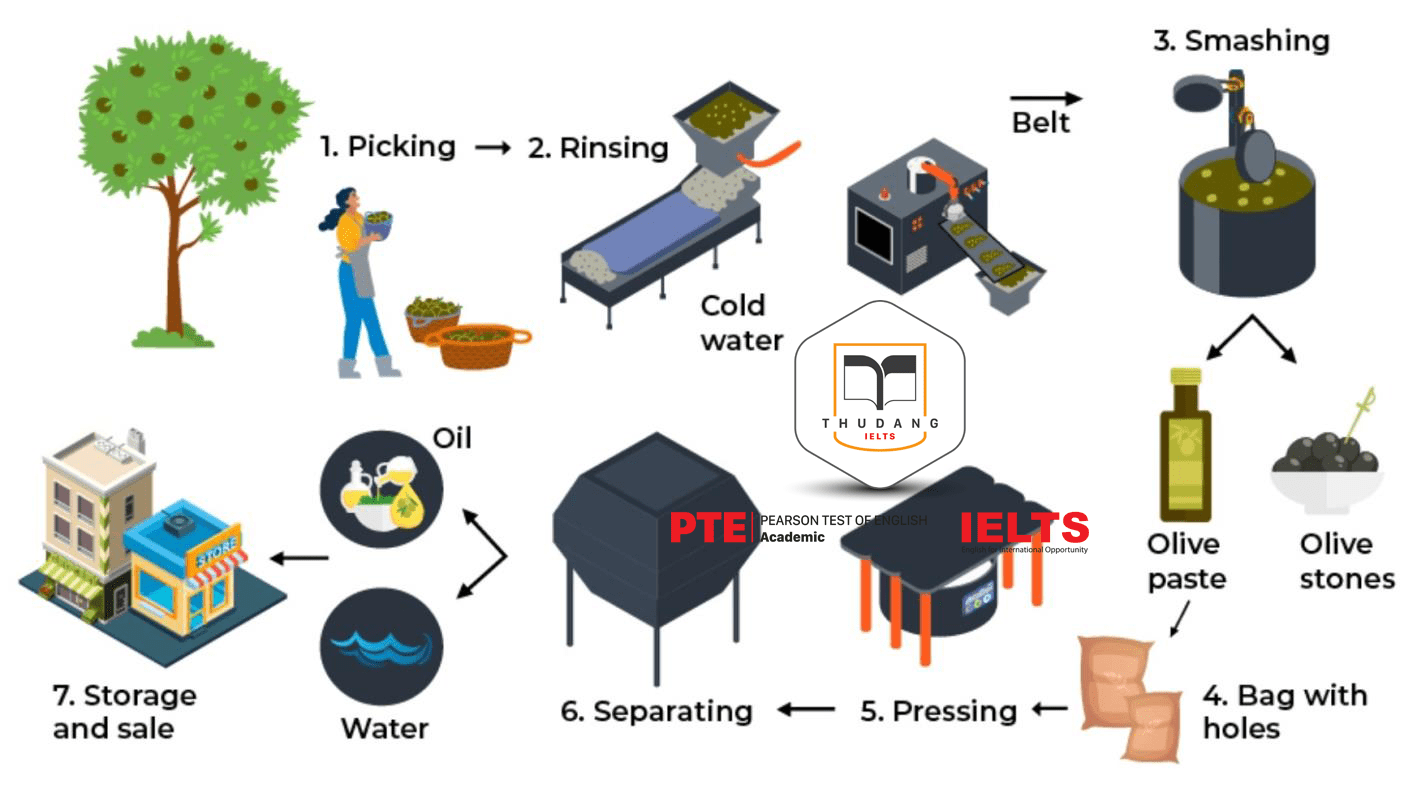

10. The diagram belows show the production of olive oil

Sample Answer:

The diagram illustrates the process by which olive oil is produced.

Overall, this is a step-by-step process that is comprised of seven stages, from the

harvesting of the mature fruit from olive trees, to the packaging and sale of the finished product.

Initially, ripe olives are harvested from trees by farmers and then taken to a rinsing

machine where they are washed in cold water. After being rinsed, the olives are

transferred via conveyor belt to another machine which grinds the olives to separate the fruit from the seeds. During this stage, the olives are ground into a paste, and the olive stones are removed.

The olive paste is then placed in a type of perforated bag before being put through a pressing machine, followed by another process where any excess water is separated from the oil. And finally, the olive oil is packaged and delivered to shops where it can be sold.

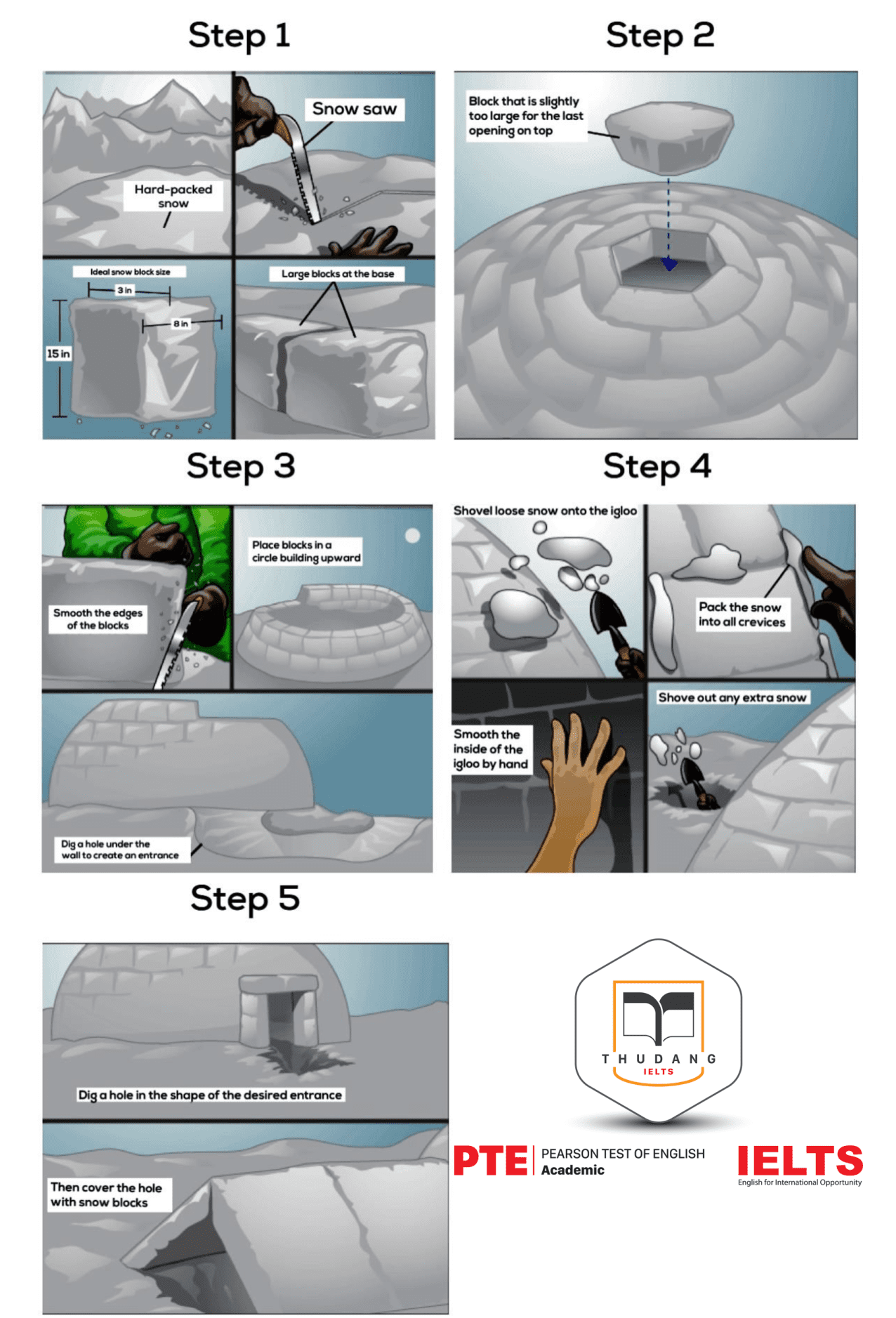

11. The illustration shows information about how igloo is build from snow

Sample Answer:

The diagram illustrates the process that is used to build an igloo from snow.

There are five main stages in this process, starting with finding an area covered by hardpacked snow and culminating in covering the entrance hole with snow blocks.

As can be seen from the process, after a surface of hard-packed snow is found, a snow saw is used to cut large blocks to the appropriate size to build the base. The edges of the blocks are then smoothed with the saw and are placed in a circle, and a hole is dug under the wall to make an entrance. Next, a slightly over-sized block is precisely shaped and placed on the top of the igloo.

Out of the remaining steps, snow is shovelled onto the outside of the igloo and is packed into all crevices while the internal surface of the igloo is smoothed by hand. Any excess snow is also removed from the inside of the igloo. And finally, a hole is dug in the shape of the entrance, and is then covered with snow blocks to complete the igloo.

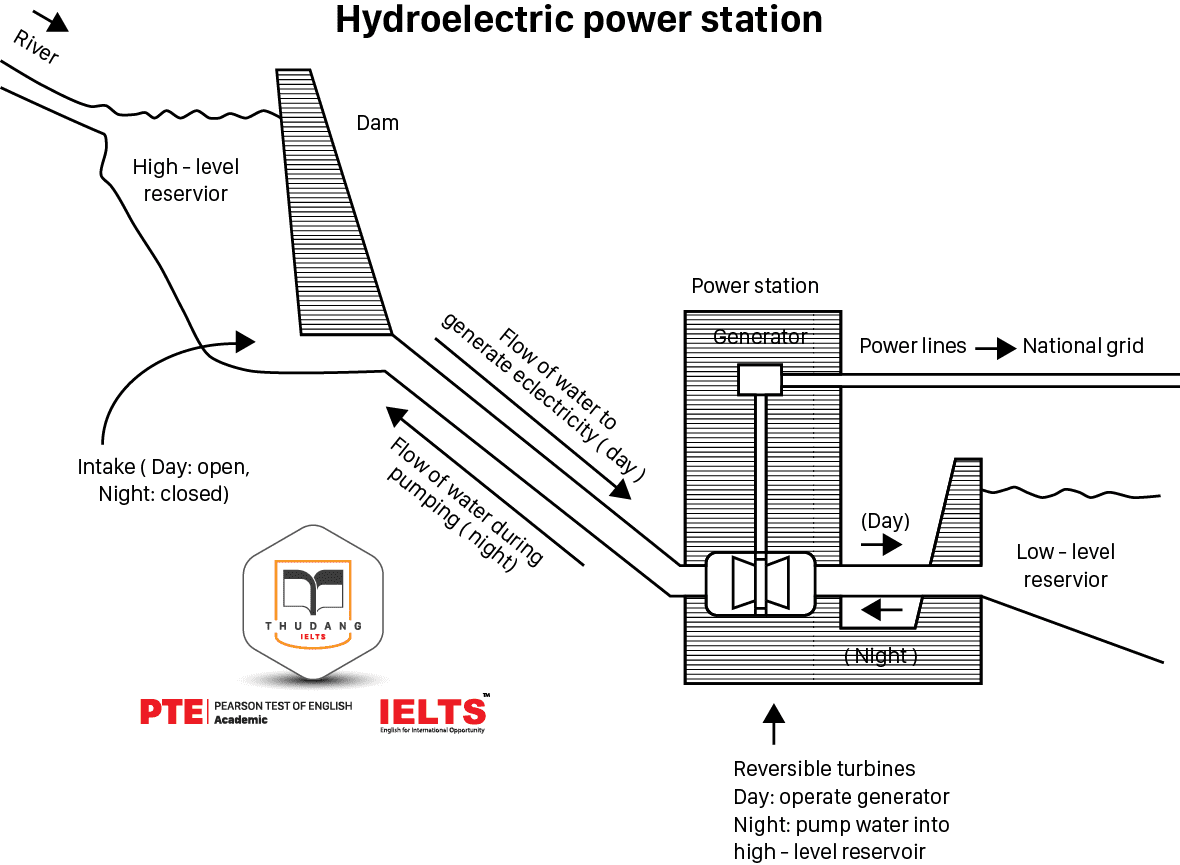

12.The diagram below shows how electricity is generated in a hydroelectric power station.

Summarise the information by selecting and reporting the main features, and make comparisons where relevant.

Sample Answer:

The diagram depicts a hydroelectric power station, and shows how electricity is generated by the flow of water through a dam and other component parts. Ultimately, water flows from one reservoir to another, producing electricity that is sent to the national grid.

Firstly, water enters a reservoir from a river. The water is held back from its natural course by a dam, underneath which there is an intake pipe that is open during the day and closed at night. During the daytime, water flows down, via gravity, to the power station, which is housed below the dam. In the power station, the flowing water spins a generator, which produces an electrical current that is then distributed via power lines to the national grid.

Once the water has generated this electricity, it flows into a lower reservoir, but at night it is pumped back up through the system to the upper reservoir, ready to begin the process again the following day.

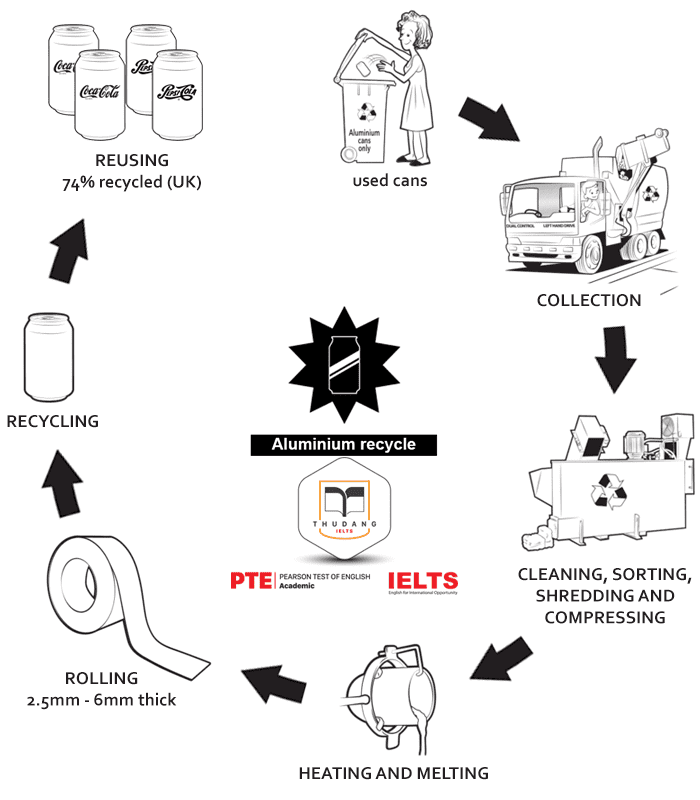

13. The diagram below shows the recycling process of aluminium cans.

Summarise the information by selecting and reporting the main features, and make comparisons where relevant.

Sample Answer:

The diagram illustrates how aluminium cans are recycled. First, the cans need to be taken to special collection centres instead of being thrown away with the normal refuse. The cans are collected from here and taken to a factory where they are first sorted and then cleaned. Next, the cans are shredded and crushed in a special machine.

The metal is then heated to a high enough temperature to allow the aluminium to melt. It is then rolled out flat to a thickness of between 2.5mm and 6 mm, depending on what it is going to be used for. The aluminium is now ready to be recycled into new packaging, such as drink containers. Finally, the new cans are delivered to a soft drinks factory where they are filled. The cans can now be sold to the public and reused. In the UK, 74 per cent of all aluminium cans that are sold are recycled.

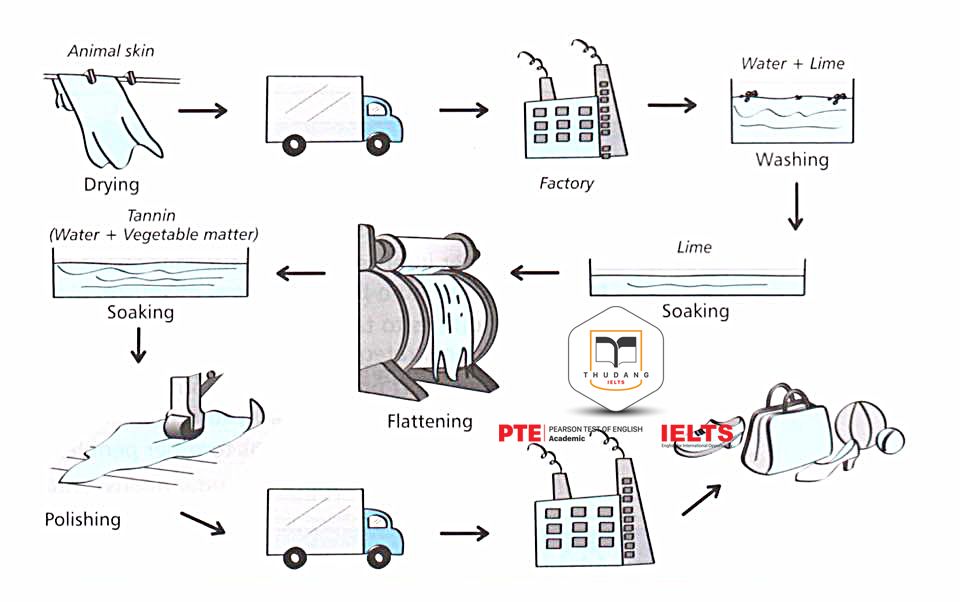

14. The diagram below show how leather goods are produced.

Summarise the information by selecting and reporting the main features, and make comparisons where relevant.

Sample Answer:

The flow chart illustrates the production line of leather goods from the source rightup until the final product.

Overall the process to produce leather items is quite a lengthy one. It involved 10 various steps of drying, transportation, soaking, flattening and polishing before finishing the product.

The first step in the production line is to dry out the animal skin. Once dry it is transported to a factory where it is washed with water and lime and then soaked in a lime solution. The leather is later flattened in a large pressing machine and soaked again, this time the solution is made up of Tannin which consists of water and vegetable matter.

Finally the leather is at the stage where is it able to be polished and transported to the factory for the last step in the process. This is where the leather is cut and sewn into various products; namely, handbags, shoes and balls.

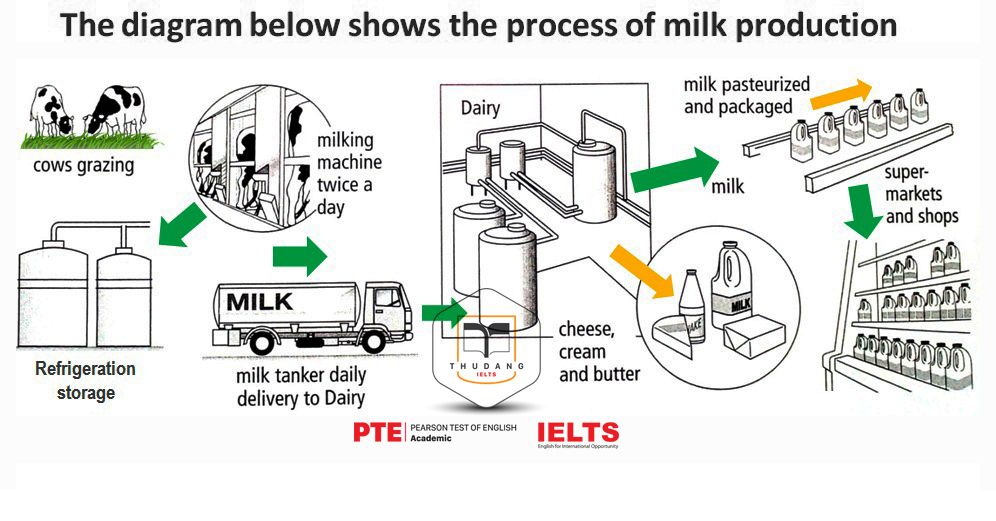

15. The diagram below shows the production and processing of milk and dairy products for commercial sale.

Summarise the information by selecting and reporting the main features, and make comparisons where relevant.

Sample Answer:

The diagram illustrates the way milk, cheese, cream and butter are produced, processed and packaged for sale to consumers.

Overall, there are 8 stages in the diagram, starting with cows grazing on grass, to the sale of dairy products in supermarkets and shops.

In the first four stages, cows graze in the fields, after which they are taken to a milking machine twice a day. Following this, the milk is put into refrigeration storage on a daily basis. Next, the milk is put into a tanker where it is then ready to be delivered to the dairy on a daily basis.

In the last four stages, once the milk is delivered to the dairy, it is subsequently put through a pasteurization process. It is then turned into various dairy products such as cheese, cream and butter. Finally, as soon as the milk and dairy products have been processed and packaged, they are then sent out to supermarkets and shops where they are ready for purchase by consumers.

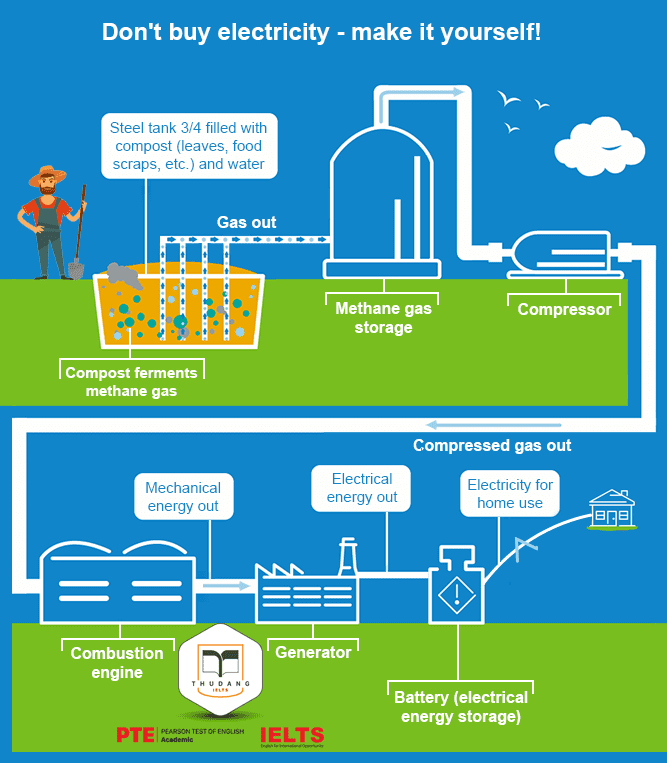

16. The diagram below shows a possible future means of home energy production.

Summarise the information by selecting and reporting the main features, and make comparisons where relevant.

Sample Answer:

The diagram shows a process for producing electricity for home use. The equipment consists of a large tank, boxes and pipes that would be able to fit into a garage-sized room.

Electricity is produced using methane gas, generated from a mix of compost and water in a large steel tank. The tank is about the same height as a person and about twice as wide. Methane rises to the top of the tank and is collected and stored in a gas storage system. The stored gas is the fuel source used in the energy conversions that happen next.

Once compressed in a gas compressor, the methane fuels a combustion engine, which in turn produces mechanical energy. Having been transferred to a generator, the mechanical energy is then transformed into electrical energy, which is then stored in a battery. At this stage the electricity is ready for home use.

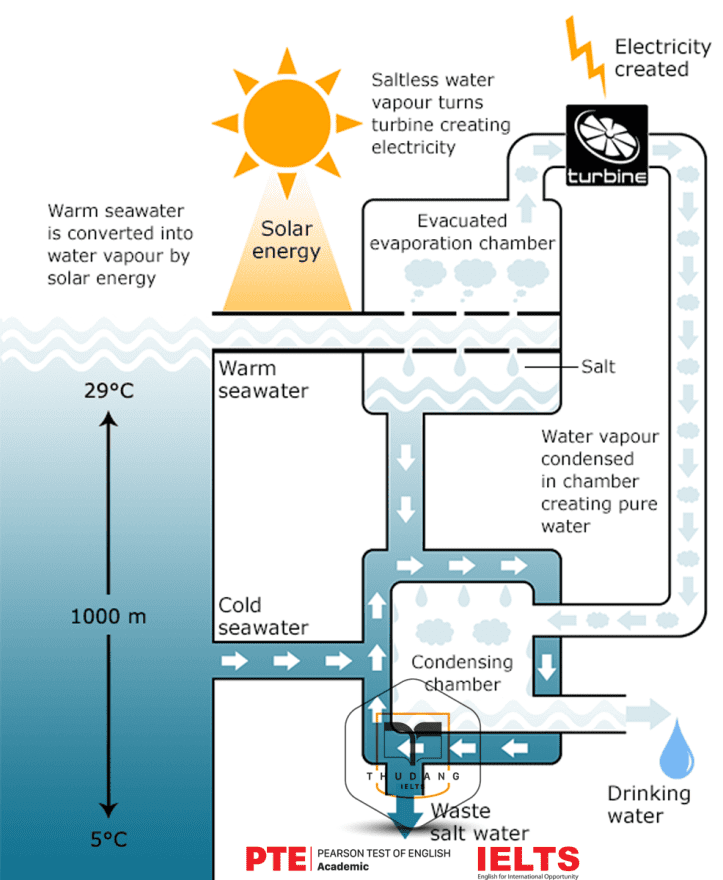

17. The diagram below shows the production of electricity using a system called Ocean Thermal Energy Conversion (OTEC).

Write a report for a university lecturer describing the information below.

Sample Answer:

Ocean thermal energy conversion (OTEC) is a system that converts heat energy into the electric power using the temperature difference between surface seawater, which can be up to 29 degrees Celsius, and deep seawater, which is only 5 degrees Celsius.

The main components of the system are an evacuated evaporation chamber, a turbine and a condensing chamber. The solar energy of the sun heats up the surface water and this warm water is introduced into the evacuated evaporation chamber, where it boils. As it boils, salt is deposited and water vapour is generated. This vapour then drives a turbine to generate electricity. After it powers the turbine, the water vapour enters the condensing chamber, which is cooled by the water from the depths of the ocean. The water vapour is condensed in this chamber, producing drinking water. Meanwhile, waste salt water is discharged into the ocean and the process can be repeated.

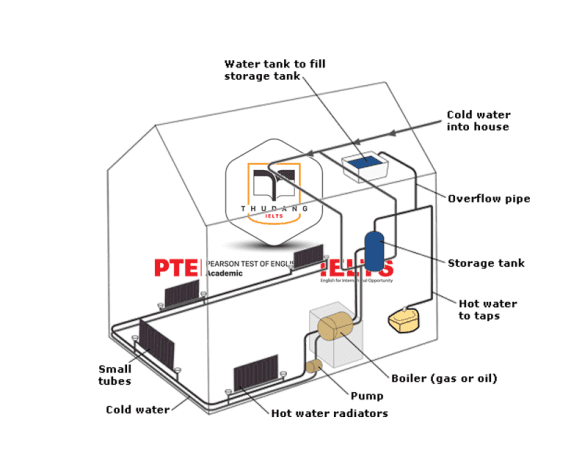

18. The diagram below shows how a central heating system in a house works.

Summarise the information by selecting and reporting the main features, and make comparisons where relevant.

Sample Answer:

This diagram provides an overview of a domestic central heating system. It shows how the tank, boiler and pipes ensure a constant flow of hot waterto both the radiators and the taps.

The cold water enters the house and is stored in a water storage tank in the roof. From there ü flows down to the boiler, located on the ground floor of the house.

The boiler, which is fuelled by gas or oil, heats up the water as it passes through it. The hot water is then pumped round the house through a system of pipes and flows into the radiators, located in different rooms. The water circulates through the radiators, which have small tubes inside them to help distribute the heat, and this warms each of the rooms. Some of the water is directed to the taps to provide hot water for the house.

Once the water has been through the pipes and radiators, it is returned to the boiler to be re-heated and circulated round the house again.

19. The graphs below show the development of the cutting tools made by stone, one was made 1.4 million years ago, and the other was made 800 thousand years ago, viewing from back view, front view and side view. Summarize the information by selecting and reporting the main features, and make comparisons where relevant.

Sample Answer:

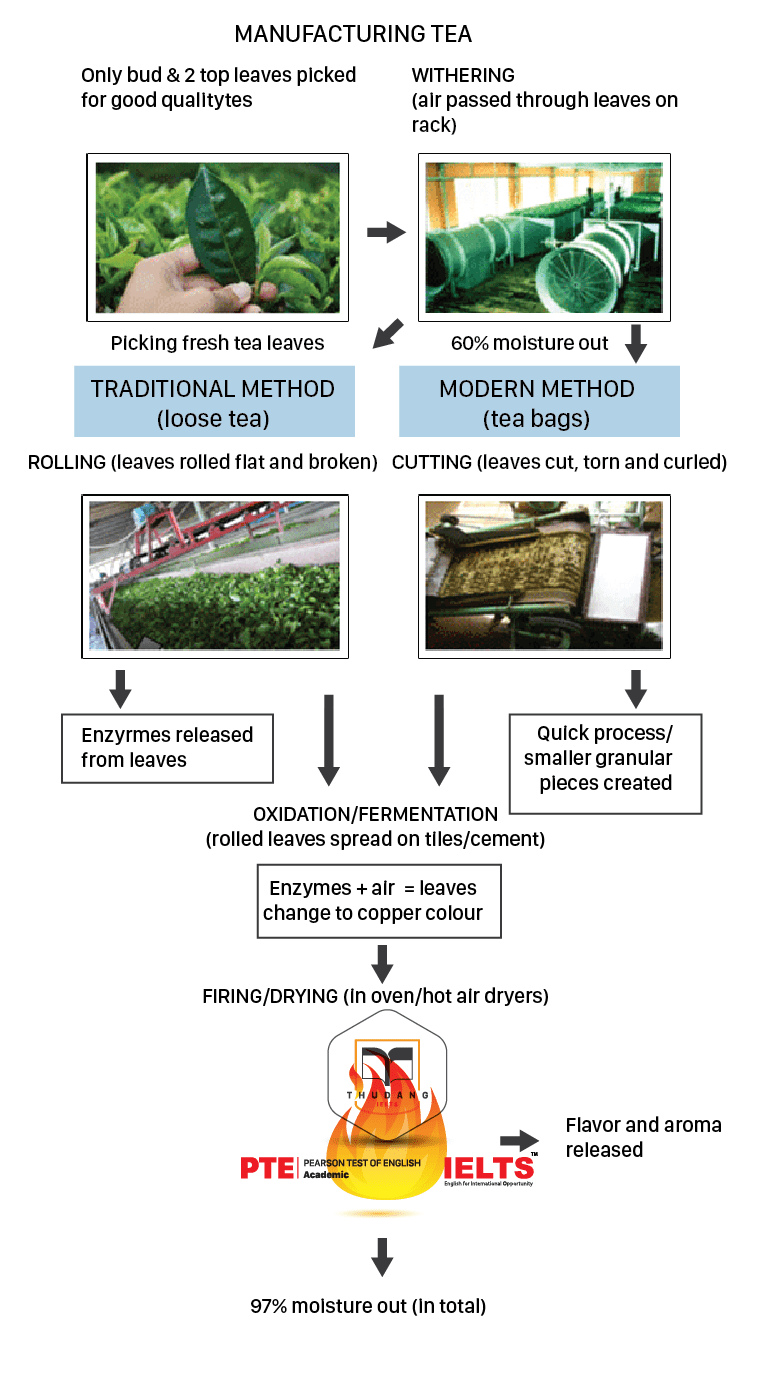

The diagram shows the two processes for manufacturing black tea. The traditional way is used for making loose tea and modern process is ideal for teabags.

When collecting tea, the tea picker picks only the two top leaves and the bud of ensure a high quality tea. Then, the tea leaves go through withering, where leaves are spread out and air is passed through withering, where leaves are spread out and air is passed through them to remove up to 60 per cent of their moisture.

After that, the leaves are ready for rolling or cutting. Factories use traditional methods of rolling and crushing or faster modern methods of cutting, tearing and curling to make teabags. In both processes, natural enzymes are produced from the leaves. The next step is oxidation, where the enzymes from the leaves mix with the air. This changes the colour of the leaves from green to copper and creates a nice flavour and aroma. Finally, the leaves are fired and dried. By this stage, little moisture remains in the tea-just three per cent.

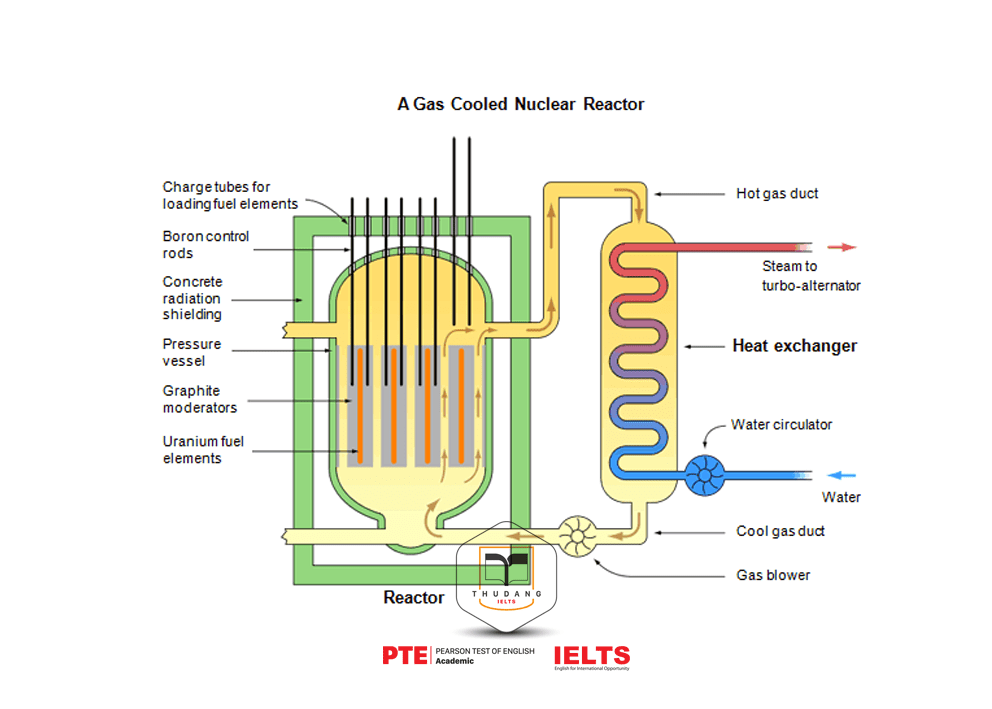

20. The diagram below shows the production of steam using a gas cooled nuclear reactor.

Summarise the information by selecting and reporting the main features, and make comparisons where relevant.

Sample Answer:

A gas-cooled nuclear reactor consists of the reactor itself and a heat exchanger. The reactor contains uranium fuel elements which are surrounded by graphite moderators and topped by charge tubes for loading fuel elements, and boron control rods. The whole reactor is contained in a pressure vessel surrounded by a concrete shield.

From the reactor the hot gas flows through a duct into the heat exchanger which is outside the concrete radiation shielding. In the heat exchanger, steam is generated in a secondary loop. There a pipe brings in water which is heated to steam, and this then flows out to the turbo-alternator. Meanwhile the hot gas sinks to the bottom of the heat exchanger and passes through a gas blower which pushes it into a cool gas duct and back to the reactor.

As can be seen, this is a continuous cycle that keeps the reactor from overheating, while carrying away the heat and steam, which will power the turbines.

Còn tiếp....!

Ngoài ra các bạn có thể tham khảo thêm một số tài liệu được IELTS Thư Đặng tổng hợp tại thư mục: http://ielts-thudang.com/download

Trân trọng cảm ơn các bạn!

Ngoài ra các bạn có thể tham khảo thêm rất nhiều nguồn tài liệu khác ở các thư mục của Website:

IELTS - Thư Đặng Tổng hợp!

.png)

.png)